Moulding system basic concepts, special constructions and control

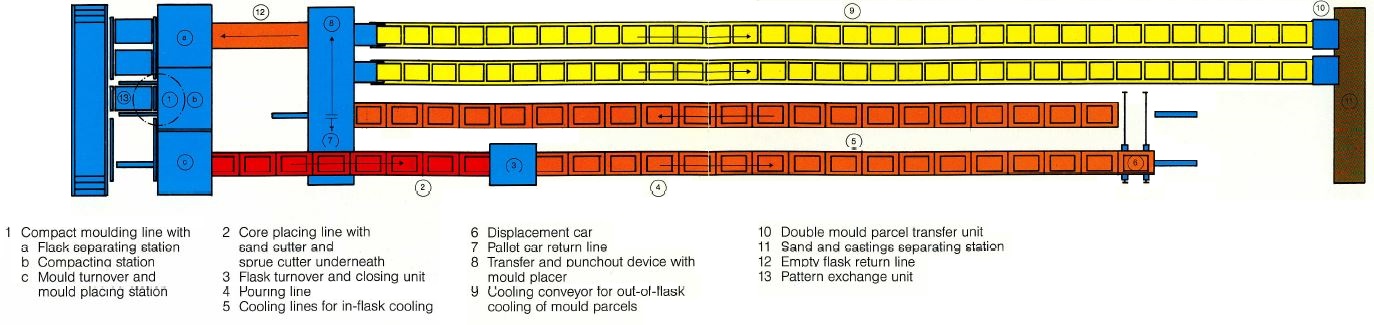

Examples of moulding line concepts

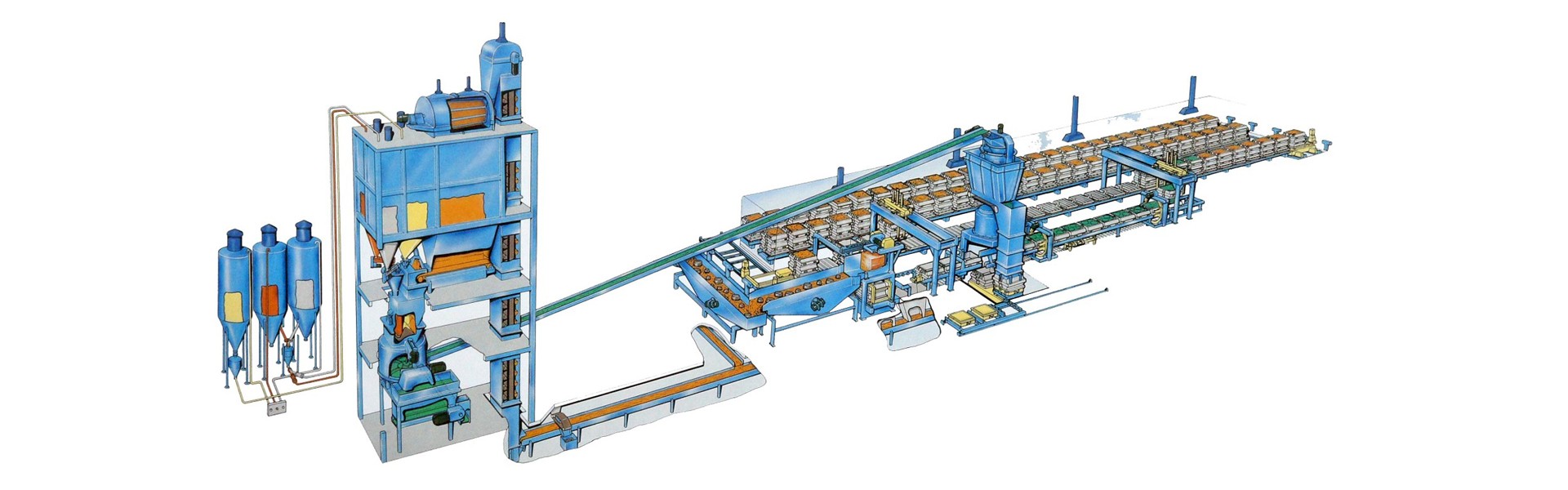

Modular moulding systems MFA = modular system

Advantages of the modular moulding line system MFA:

Coverage of a large flask area according to customer requirements and system output up to approx. 220 moulds/h, the output depends on the flask size

- Optimal system configuration according to the available space. The compact design requires only a minimum of foundation work

- Faster and gentler mold transport thanks to electronic drives

- Low maintenance and easy access to all system parts

- Well-engineered technology with high reliability in everyday foundry work

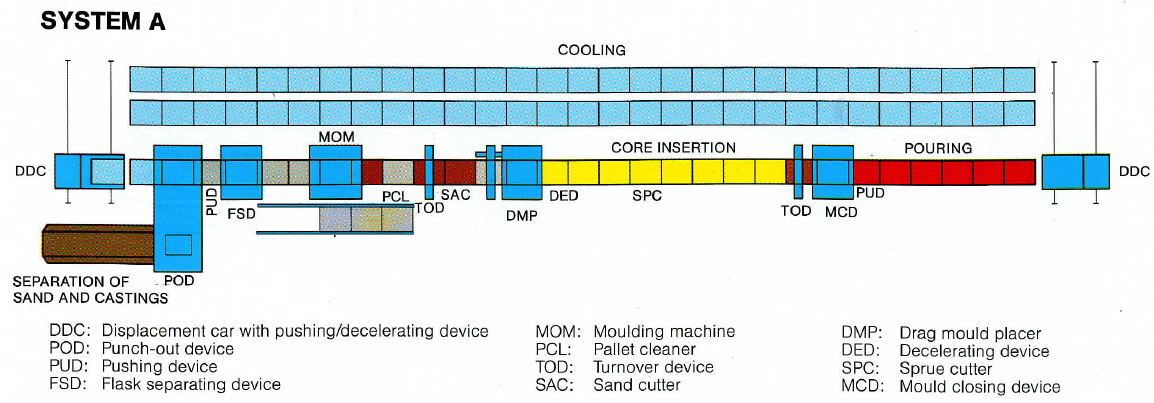

Examples System A:

Examples System CS:

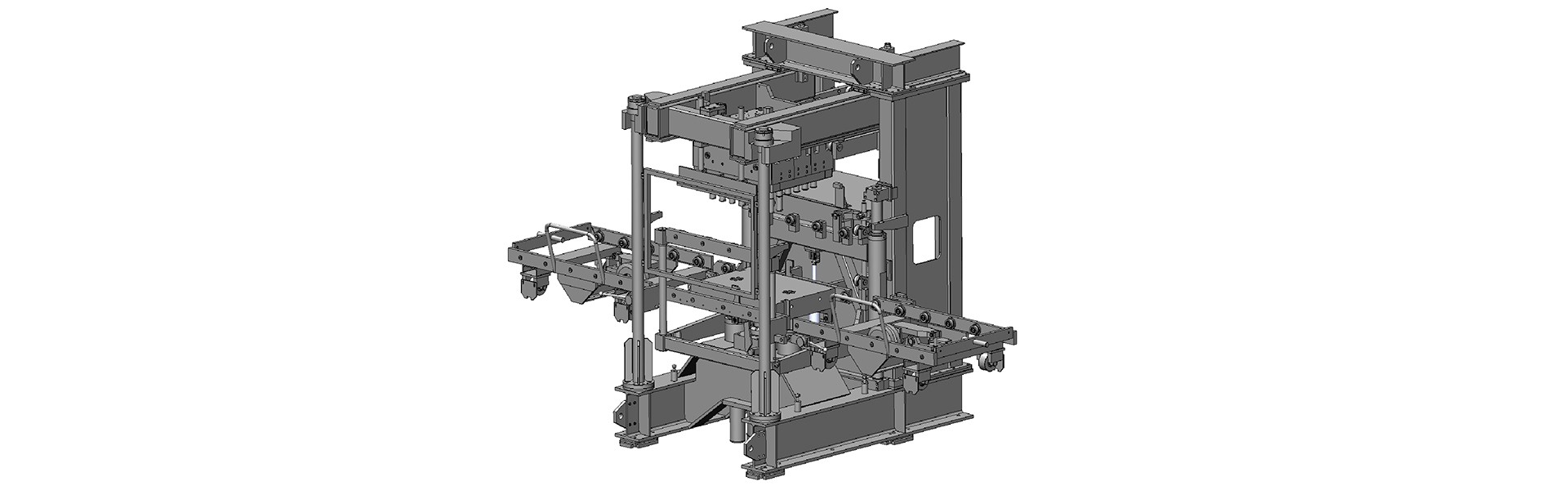

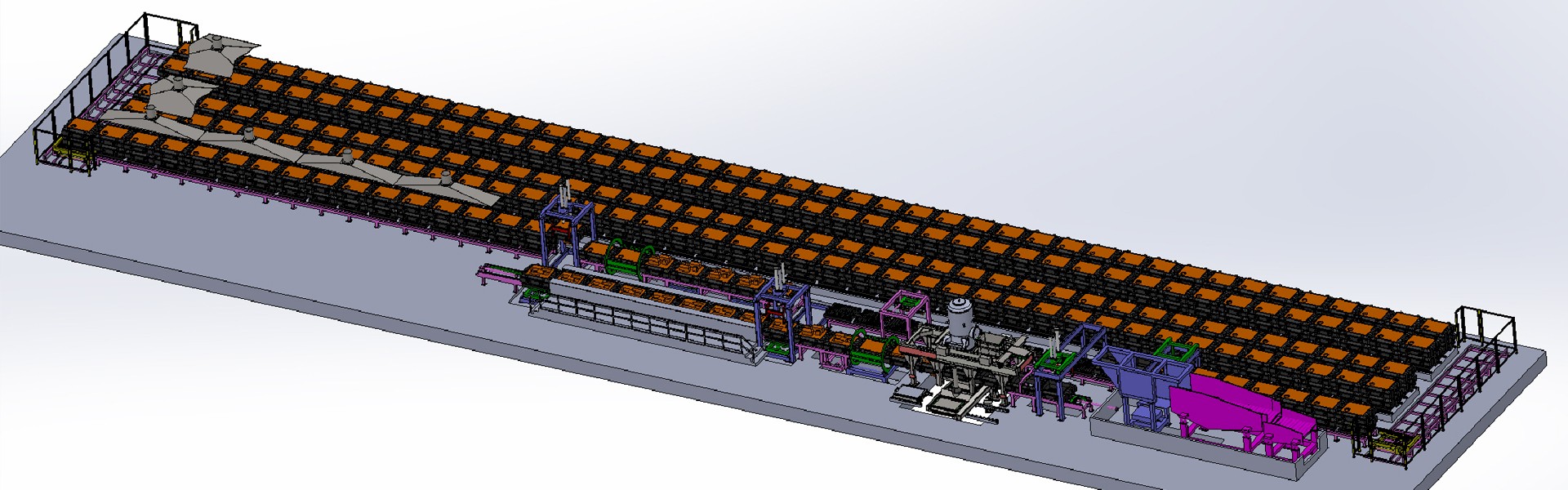

BMD moulding line concept: CAL (compact design)

Key Features:

- Compact line with both DYNAPULSE and Vario-Air-Impulse moulding machines

- The moulding machine is turned by 90° to the pouring and cooling lines

- Modular structure according to customer requirements

- Small space requirement due to compact design